Add Date: 2024/12/27 Views: 1

The small five-axis simultaneous machining center utilizes a CNC system to programmatically control the coordinated movement of five axes. Each axis operates independently, but through the control of the CNC system, these axes can achieve precise synchronization and coordination to complete the machining of complex surfaces and irregular shapes.

In the small five-axis machining center, the x, y, and z axes are the moving axes responsible for lateral, longitudinal, and vertical movements, respectively. The a-axis rotates around the x-axis, and the c-axis rotates around the z-axis. These five axes can form a simultaneous machining system, making the machining process more flexible and capable of achieving high-precision machining of complex surfaces.

The small five-axis simultaneous machining center adopts high-precision screws, guides, bearings, and other components, ensuring the machine's positioning accuracy and repeatability, which results in higher machining accuracy of parts and significantly improves the yield rate.

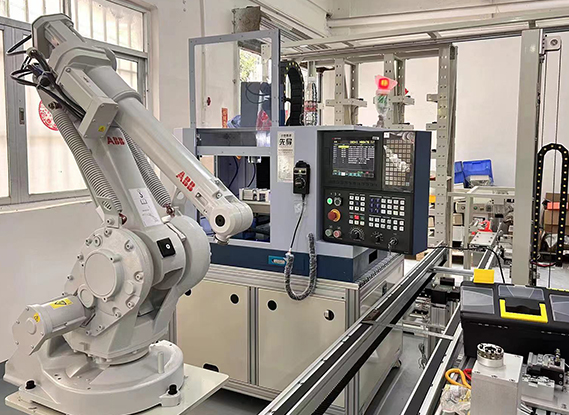

The VMC300-5 small five-axis CNC machining center has dimensions of 1360×1080×1830mm, operates on a 3.380-volt power supply, occupies a small footprint, and consumes less power. It combines transparent acrylic with sheet metal, enhancing viewing safety while ensuring the structural stability and full enclosure of the machine.

It features a 12-station tool changer with a 0.6Mpa air pressure requirement, five-axis simultaneous control, an industrial-grade CNC system, compatibility with internationally standard programs, automatic fault detection and alarm functions, and power-off memory function.

In addition to the machining center, there is also the C220-5 pilot desktop five-axis simultaneous CNC milling machine. Its bed is cast from high-quality cast iron material, quenched with ultra-audio frequency, and precision-ground to ensure the machine's rigidity and accuracy in machining. The machine is sturdy, stable, and durable, executes universal G-code programming, and is compatible with FANUC and various CAD/CAM software.

The bed and rotary table adopt a cast iron vertical structure, with XYZ axis linear guides and the spindle column driving the tool movement. It features a reducer with a cradle-type rotary table, a fully enclosed protective cover, a vertical lifting door, and a machine door safety protection device.

By operating the five-axis simultaneous machining center, students can enhance their CNC programming and operation skills, laying a solid foundation for their future career development.

The five-axis simultaneous machining center provides students with a real operating environment, allowing them to learn and master five-axis simultaneous technology through practice. This hands-on experience helps deepen students' understanding of theoretical knowledge and improves their practical operation skills.

The small five-axis simultaneous machining center is widely used in various fields such as aerospace, rail transportation, medical equipment, military research, precision instruments, shipbuilding, and yachts, particularly suitable for machining complex surface parts and workpieces with complex shapes such as spiral grooves.

EN:

Keyword:# Small machining center, # Desktop machining center, # Small five axis machining center, # Desktop teaching machining center, # Pilot five axis linkage machining center

WEBSITE:www.xendolltools.com

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll